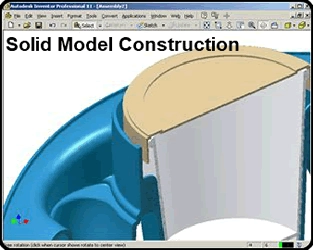

Develop Solid Model

A Solid Model is much more than a 3D digital image on a computer. Plastic Design, Mechanical Engineering, and Industrial Design expertise is applied during the construction of a Solid Model of your product.

The Solid Model of your product becomes the cornerstone for the rest of the project. It can be used to:

- Create Virtual Prototypes for your review on your computer.

- Perform stress analysis, fit and function, and performance testing.

- Produce plastic prototypes using Stereolithography.

- Program tooling paths for prototyping and production tooling.

- Generate patent graphics.

- Construct mechanical drawings of components and assemblies.

For the security of your product information, we provide a Non-Disclosure Agreement Form that allows you to easily generate a Non-Disclosure Agreement (NDA). An NDA is simply an agreement that restricts our use of your information. While we have no interest in profiting from your product information, an NDA is a written agreement that states that we will not disclose your information to anyone you do not want the information disclosed to. It also states that we will not profit from your information in any way.

Click here to generate an NDA. You'll need to sign it and send it back to us. The last paragraph on the NDA explains how.

Helpful Links

Fill out Your Non-Disclosure Agreement

Non-Disclosure Agreement Form

Legal Help

US Patent Office

Patent Search

Patent Attorney Search

Legal Zoom

Miscellaneous

California Consumer Affairs

California Board for Professional Engineeers and Land Surveyors

Dexigner Directory